Dyeing and finishing

Over the years, the company has evolved to meet all customer needs, specializing in the piece dyeing of fabrics made with mixed fibers such as wool, silk, linen, cotton, viscose, etc. and is now able to offer an ideal finished product for men's and women's clothing , accessories and furniture.

Furthermore, Iride stands out for having increased and expanded the study of various types of finishing in order to give the fabric particularly sought-after characteristics and aspects. Over the years, the dyeing department, where all items are treated in rope, has also been expanded and improved. Iride offers several treatments including preparation, washing, punching, washed linen and foulard treatments such as water-repellent, hardening hand, super-black and many others; it ennobles fabrics with classic and vintage hands thanks to Enairgy drying. Finally, there is an internal brushing department.

In order to be always at the forefront, Iride has continued to invest in new and innovative machinery. Regarding the wet finishing department, in January 2018 a new machine for a cold impregnation system dedicated to cotton, linen, viscose, etc. with the possibility of making soda treatment was tested. In 2023, a new generation continuous washing system was purchased which reduces water and energy consumption. As for the dry finishing, in recent years the KD, the continuous decatizer and the vaporize have been replaced with just as many of new generations signed Biella Shrunk Process to improve quality and production capacity.

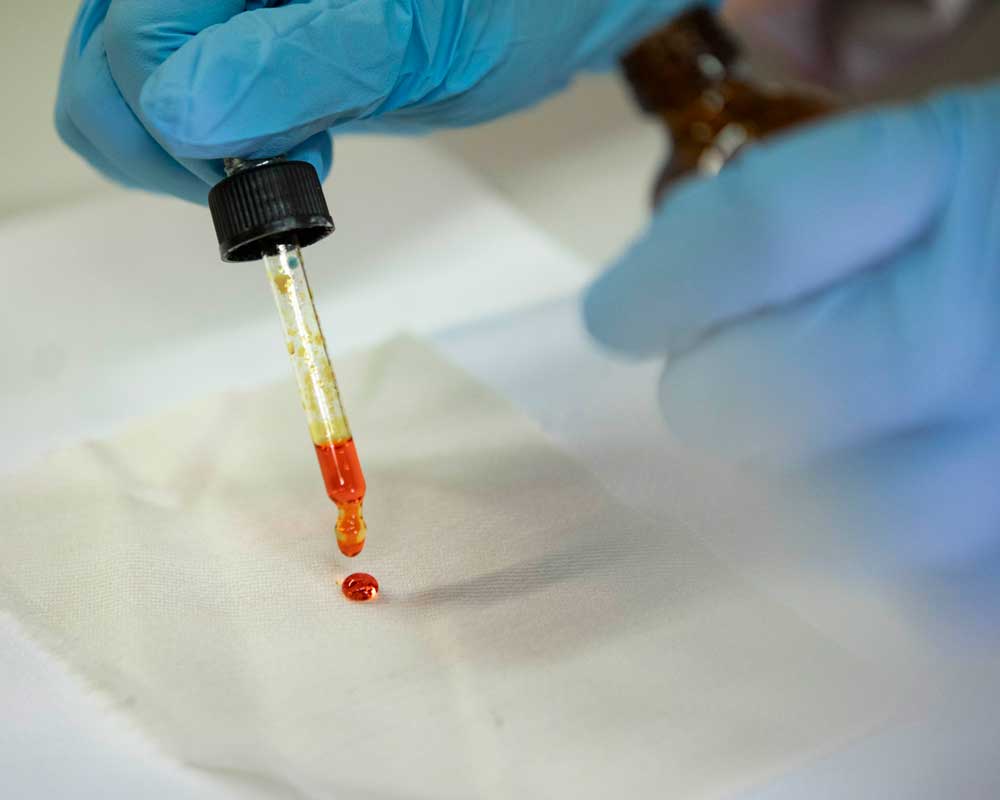

The finished fabric control department and the laboratory complete the company. The laboratory develops lab dips, performs first tests on textiles and, above all, prepares colour recipes. Finally, in addition to a first check carried out in the dedicated area on the ground floor, on the first floor is located a local unit of the company TessilControll System, dedicated to the inspection of all production.